Biolac®, an extended aeration, activated sludge treatment system, is a well-accepted biological wastewater treatment process with hundreds of successful installations treating municipal and industrial wastewater. Using an innovative long sludge age, activated sludge process, our complete system provides an extremely simple and cost-effective solution for many treatment applications.

The Biolac Process

- Uses longer hydraulic retention times with more biomass in the treatment process, providing a process that is extremely stable and able to handle fluctuating loads and flow with minimal operator intervention and without pre or post equalization.

- Reliably produces single digit effluent BOD/TSS and excellent biological nitrification, consistently removing ammonia to well less than 1 mg/l, even in single digit wastewater temperatures.

- Simplifies total nitrogen removal using the Biolac® Wave-Ox™ process. Automatic DO and aeration control create multiple oxic and anoxic zones in a single treatment basin, eliminating the need for separate anoxic mixers and MLSS recycle flow and pumps. As a result, BNR energy usage is reduced by 20-30% vs. traditional BNR processes. Using the Wave-Ox™ Plus process with ammonia based process control reduces energy consumption further.

- Produces minimal quantities of well-stabilized, excess biomass that typically requires no further sludge treatment after leaving the process.

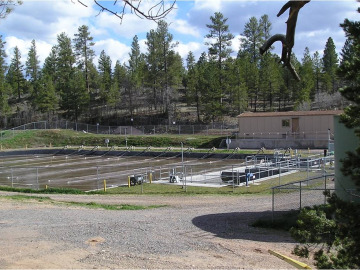

Most Biolac systems provide all these process capabilities in one easy-to-construct, lined, in-ground earthen basin. This simple construction and the elimination of numerous other treatment steps (i.e. equalization, primary clarification, digestion, etc.) make the Biolac system a very cost-effective and simple to operate solution. Many times an existing basin or lagoon can be modified to fit the Biolac system, making it ideal for upgrading and retrofitting existing lagoon treatment systems.

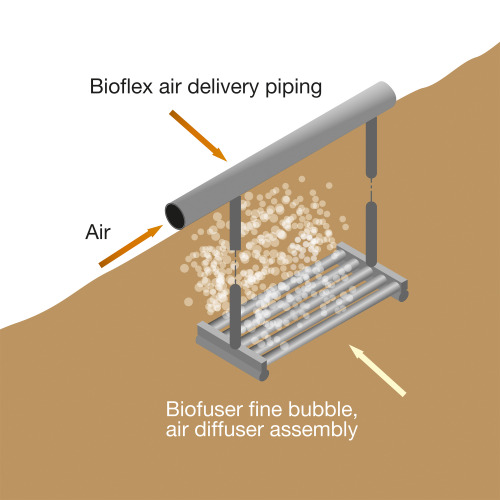

The unique Biolac moving aeration chain system for mixing and oxygen transfer brings all these features and capabilities together. Developed by Parkson in the mid-1980s, the floating aeration chains suspend Biofuser® fine bubble diffusers approximately one foot above the basin bottom. Because there are no points of attachment or support to the basin bottom, all equipment is easily accessible and removable for service and maintenance without basin dewatering, eliminating the need for redundant treatment basins. The flexible, floating aeration chains systematically move through the wastewater propelled only by the rising air bubbles from the diffusers. As a result, the Biolac moving aeration chains are extremely efficient mixing devices, requiring only 1/4 - 1/3 of the energy for complete mixing compared to stations diffused air or mechanical aeration systems. This unique mixing capability is the key to providing operating flexibility and efficiency in a long sludge age process.

The Biolac system design is completed by the Biolac® EZ Clear™ secondary clarifier. Common wall construction between the EZ Clear™ clarifier and effluent end of the treatment basin minimizes the plant footprint and construction cost while providing significant operational and process advantages:

- Incorporates an airlift sludge return system within the clarifier itself, eliminating the need for mechanical RAS and WAS pumps

- Dampens peak flow through the clarifier using automatic in-basin equalization

- Simplifies and reduces construction costs by eliminating splitter boxes, field piping and RAS/WAS pumps and pump stations

- Reduces the plant footprint by 50% vs. a separate clarifier design, allowing the plant to be constructed on a much smaller site

- Minimizes hydraulic loss between the treatment basin and clarifier discharge

Phosphorus removal can be accomplished either chemically by adding coagulant, or biologically by incorporating an anaerobic Bio-P zone in front of the Biolac treatment basin in a traditional biological phosphorus removal approach.

Contact us today to receive a system design recommendation for your plant.