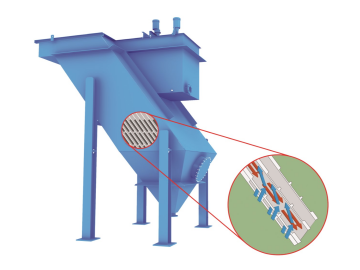

Lamella Clarifier

The Lamella® is the original inclined plate clarifier. Introduced by Parkson in 1971, it has been the industry standard for this technology.

How It Works

The Lamella clarifier works when a solid/liquid stream that has been flocculated, enters a tank, and flows upward between a pack of inclined plates. The solids fall to the plate surface, where they slide by gravity down to a sludge collection hopper. The clarified effluent flows through orifice holes and exits the top of the settler.

The innovative Lamella EcoFlow®, which was unveiled in 2012 and is patented, eliminates the area of interference at the bottom of the plates and allows for full utilization of the plate settling area. This translates to an increased capacity of 25% in the same footprint and allows for easy retrofitting to upgrade older installations to the EcoFlow® design!

The Lamella has Been Utilized in Countless Applications Including:

- Potable water clarification

- Industrial process water

- Sand filter backwash

- Metal finishing

- Mining

- Groundwater

- River pre-sedimentation

Looking for additional information? We're here to help.