The IGNITE™ Integrated Nitrification process is a non-activated sludge solution for upgrading lagoon based treatment plants to achieve improved BOD and ammonia removal. The process utilizes a combination of Parkson’s Biofuser® lagoon aeration system and the TumbleOx™ Nitrification Reactor process.

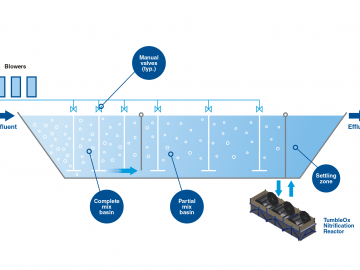

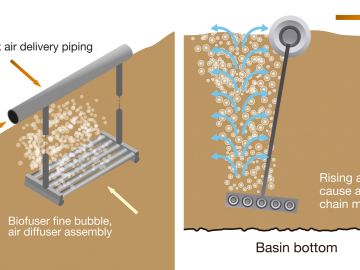

The process flow scheme consists of a complete mix lagoon cell, partial mix cell, TumbleOx Nitrification Reactors, and a settling zone. In the complete mix cell of the lagoon, mixing and aeration are provided for organics (BOD) removal in a relatively small cell volume. A partially mixed secondary aeration cell with adequate volume to remove most of the remaining BOD is provided. The secondary cell also achieves some nitrification. Both the complete mix and partial mix cells are aerated and mixed utilizing Parkson’s Biofuser lagoon aeration system (see Biolac® product features). Partially nitrified wastewater from the partial mix lagoon cell then flows through the TumbleOx Nitrification Reactor.

TumbleOx™ Nitrification Reactor

The TumbleOx Nitrification Reactor is an attached growth process that utilizes media stored in a rotating mesh drum which is partially submerged in the wastewater. The drum rotates, creating energy to mix the tank and ensuring thorough contact of the ammonia with the bacteria attached to the media. The media is shaped to create a bailing effect which cups and lifts the wastewater above the surface as the drum rotates. The wastewater is dumped from the media above the water surface, allowing oxygen to be dissolved into the wastewater as it falls back to the water surface. This continual movement of the media in and out of submergence creates a high level of dissolved oxygen in the tank which is necessary to convert ammonia to nitrate. Dissolved oxygen levels are typically maintained above 3.0 mg/L without the use of blowers or aeration systems. The small horsepower drive unit on each drum allows aeration and mixing to be achieved very efficiently with minimal power costs.

The constant movement and contact of the media pieces within the drum prevent excessive buildup of biomass on the media. A thin, healthy layer of autotrophic bacteria is maintained on the media surface for optimum nitrification.

TumbleOx reactors can be purchased individually for installation within site-built tanks, or purchased as three (3) drum pre-packaged units with tank. The pre-packaged units are completely factory assembled so site installation only consists of connecting inlet and outlet piping and terminating field electrical wiring at one common control box.

Advantages of the IGNITE Integrated Nitrification Process

- Coordinated process design and process guarantee. All equipment is provided by Parkson.

- Ability to achieve tighter BOD, TSS and ammonia permit limits with minimal upgrades. Existing lagoons are typically utilized.

- Simple operation by treating with a non-activated sludge process. No clarifiers or sludge recycle.

- Initial capital cost and long-term operational costs are lower than activated sludge or other treatment options.

- Upgrades can occur while the existing plant remains in service.

Looking for additional information? We're here to help.