The Hycor® ThickTech™ Rotary Drum Thickener (RDT) is the industry leading sludge thickener. Its performance is unmatched, with sludge volume reduction of 90% and a 98% capture rate. In addition, this superior performance is achieved with very low amounts of polymer. The RDT system is quite compact and requires less floor space than other thickeners. It has low requirements for horsepower, water consumption and polymer usage, resulting in valuable operational efficiencies.

The RDT increases digester capacity, reduces hauling costs and can be used as a pre-thickener to increase capacity of other dewatering equipment.

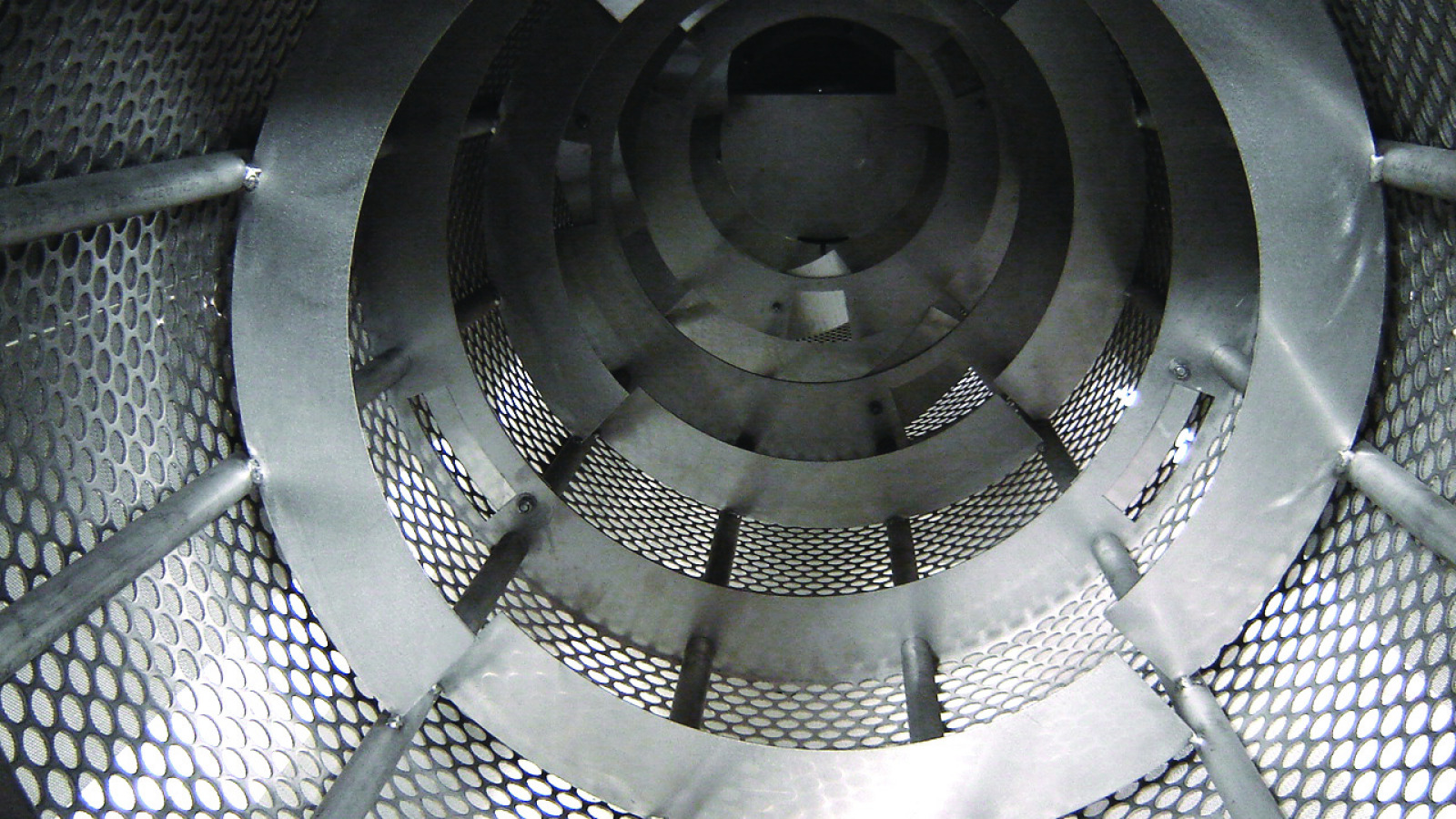

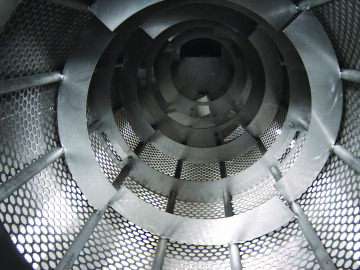

With hundreds of installations and over 25 years of operation, the ThickTech™ system is performance proven for applications in municipal water and wastewater treatment plants, industrial facilities, and pulp and paper mills. It is fabricated of stainless steel, and engineered to provide years of reliable service. The system utilizes a low shear floc tank, followed by dewatering with a high-performance rotary drum screen.

How ThickTech Works

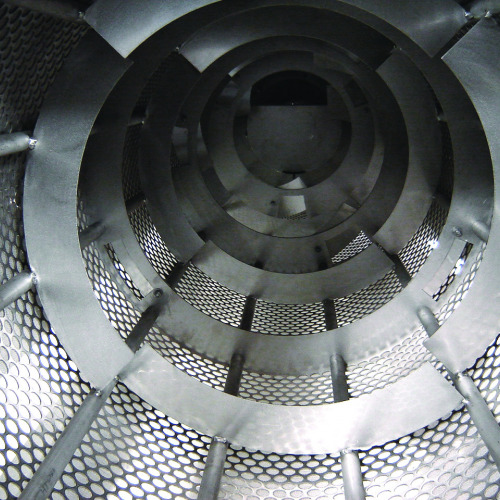

The sludge thickening system is designed to achieve flocculation with a minimal amount of expensive chemicals. The floc tank has tangential inlet and outlet openings to maximize flocculation by reducing shear from turbulence. This design creates a gentle swirl that combines the sludge with the polymer. This swirling motion also increases the overall sludge detention time for floc development. A specially designed impeller maintains the swirl without breaking down the flocs.

Dewatering takes place along a multi-zone drum cylinder. The zones can have different size mesh media to augment capture efficiency as the sludge moves along the length of the cylinder. Finer mesh is generally used in the feed end where material is thinner, while downstream zones have larger openings to enhance water removal. Rings with adjustable ports control detention time in each zone. The result is capture efficiencies as high as 98% without sacrificing high inlet flow rates. High capture efficiency alone can substantially reduce polymer usage.

Looking for additional information? We're here to help.