Rotating drum screens with perforated plate screen media are the most successful solution for screening prior to a Membrane Bio Reactor (MBR) system. Because Rotoshear® PF uses Rotoshear’s base structure, it is the most reliable and highest capacity rotary drum fine screen for an MBR plant.

More than 40 MBR plants use Rotoshear PF as their MBR pretreatment screen. Additionally, over 100 units are running in the country at a 5 MGD+ (3500 gpm) flow rate per screen. These are claims no one else can make.

Unlike center-flow band screen technologies, Rotoshear PF does not allow bypass of solids larger than the screen opening. Plants using other technologies often face problems with membranes fouling. As a result of those problems, several plants switched to Rotoshear PF to eliminate their concerns about membrane fouling.

How the Rotoshear PF Works

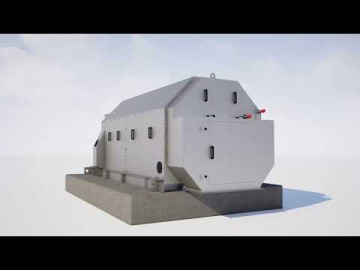

The Hycor Rotoshear PF is an internally fed rotary perforated plate cylindrical screen that operates with minimal attendance. Influent enters through the inlet and flows into a headbox. The headbox fills and the influent cascades over the weirs and contacts two sides of the rotating cylinder screen. As the influent hits the turning screen, the solids are caught inside the cylinder and the liquid passes through the screen into the process, or on for further treatment. Diverters on the cylinder move the solids along the length of the screen to discharge. The unit is equipped with spray bar(s) to clean the screen.

Screen openings are available in 1mm (0.039”) or 2mm (0.079”). Other sizes are available upon request. The material standard is 304 stainless steel, while 316 and L grades are available as well.

Product Video

Looking for additional information? We're here to help.