The Granite AGS™ process is a cutting-edge technology designed to improve the performance of activated sludge systems. The process produces biomass in a granular form which is much more dense than typical activated sludge floc. Utilizing densified sludge greatly improves the reliability and efficiency of the secondary treatment process. For the last 100 years, the main focus of biological wastewater treatment has been the use of activated sludge. In these systems, aeration, and bacteria selection are critical to maintaining the right environment for floc formation. Over the years, various configurations have been developed to achieve lower levels of nitrogen (N) and phosphorus (P) through the use of multiple tanks, biological selectors, media carriers, and chemical addition with further clarification and filtration. All in all, activated sludge in all its variations is the norm in the industry.

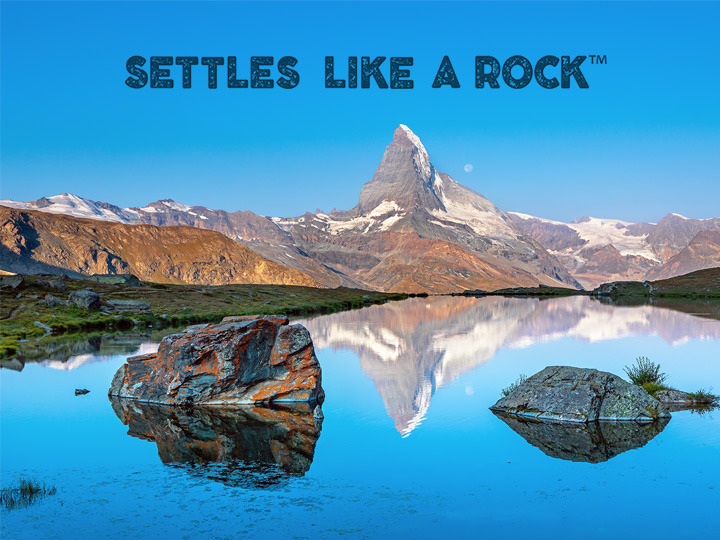

What makes the Granite AGS™ product unique is the ability to form granular sludge rather than typical floc-forming sludge through a patented process. The advantages of aerobic granular sludge are excellent settleability and robustness of the biological colony. The settleability of the granules is more than 5 times faster than a conventional activated sludge floc due to the dense nature of the colony. Having a denser, better settling sludge allows plants to be designed with smaller treatment basins, reducing capital costs, and providing greater sustainability given more efficient operation.

Key Features of Aerated Granular Sludge

1. Nature's Efficiency:

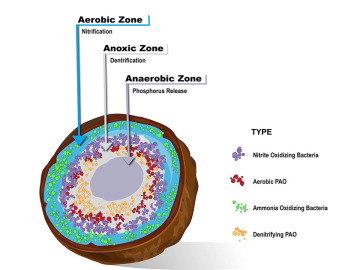

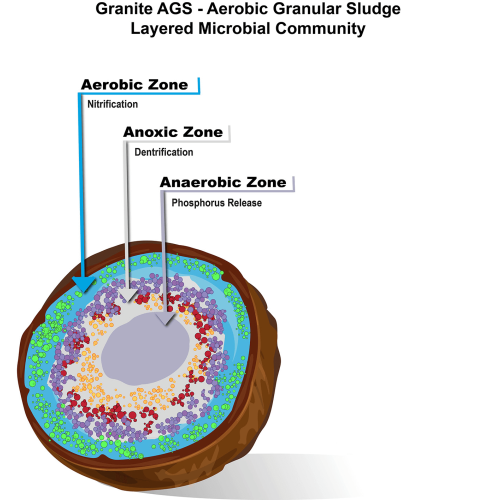

Aerobic Granular Sludge fosters the growth of robust microbial communities (Heterotrophic, Nitrifiers, Denitrifiers, PAOs, and GAOs) within compact granular structures. These dynamic microorganisms work synergistically to effectively remove nutrients from the wastewater.

2. Reliable Performance:

Granular sludge compacts very well resulting in SVI’s (Sludge Volume Index) of around 50 ml/g. The highly compacted sludge provides a greater interface between the settled solids and the clear effluent that is removed from the upper portion of the basin.

3. Space- Saving Design:

Excellent settling and compaction characteristics allow the system to be designed at a much higher MLSS concentration when compared to conventional activated sludge. This greatly reduces tank sizes, footprint, and overall cost of construction. Existing systems can be retrofitted to increase treatment capacity within existing tankage.

4. Lower Energy Consumption:

Smaller treatment basins require less mixing energy so overall power consumption is reduced. Aerobic conditions are achieved by utilizing highly efficient fine bubble diffusers.

5. Enhanced Process Stability:

Utilizing a densified sludge provides more resilience in terms of maintaining treatment during sustained high peak flow events. Solids washout, which can be a problem with typical floc-forming bacteria, is much less likely with the heavier granular sludge.

Sequence of Operation

1 - Anaerobic Fill

- Operated in series with one tank being filled at any given time.

- No aeration occurs during this period, and Oxygen Reduction Potential (ORP) is monitored.

- Anaerobic conditions encourage the production of Extracellular Polymeric Substances (EPS).

- EPS is key in the creation of granular sludge particles

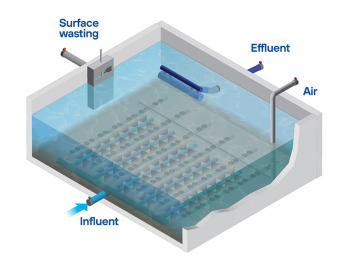

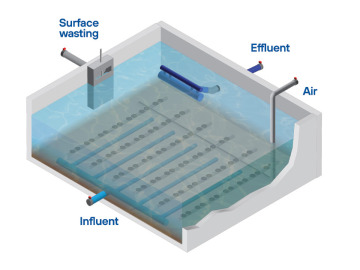

2 - React

- Flow diverted to the next basin.

- Aeration and mixing occur until complete biodegradation of organics is complete.

- Luxury uptake of Phosphorus takes place.

- Surface wasting of mixed liquor.

- Waste sludge transferred to the Sludge Thickening Tank.

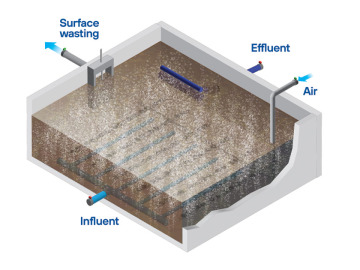

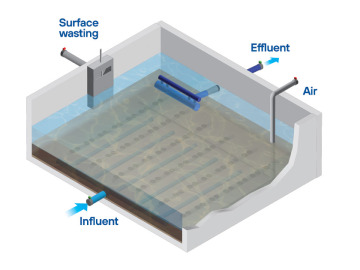

3 - Settle

- No influent enters the basin.

- No aeration or mixing to create perfect quiescent conditions.

- The entire reactor basin volume is used for solids separation.

4 - Filled Decant

- Effluent withdrawal occurs.

- Anaerobic fill begins.

- The Influent Distribution System is utilized to allow for low inlet velocities.

- The sludge blanket remains compact

Looking for additional information? We're here to help.