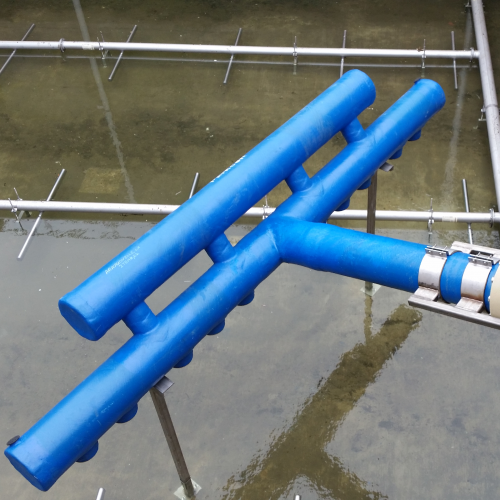

Parkson offers two options for liquid removal from water and wastewater basins: effluent and supernatant decanters. The Parkson DynaCanter™ is a floating decanter used to remove treated effluent or supernatant from the upper portion of the basin. The floating decanter utilizes a flex joint to allow vertical articulation as water levels move between high and low water levels. The decanter collects water from below the surface to preclude foam, scum, or other floatables from the effluent. A standard open/close valve is used in the effluent piping to control flow rate through the decanter. No electro-mechanical components are used inside the basin, making operation and maintenance convenient for the operator.

For the effluent-style decanter a series of check valves are provided in the decanter drawtube to isolate the effluent piping from the mixed liquor during mixing and aeration steps, and thus ensuring clear effluent is being removed from the basin. In the supernatant design, the plugs are replaced with machined orifices and the piping is turned upward to allow removal of liquid closer to the surface.

The basic principle behind the design of the DynaCanter effluent decanter is to utilize spring loaded check valves to isolate the effluent piping from the surrounding mixed liquor when the tank is aerated and/or mixed. The hydraulic profile is configured to allow head pressure to open the spring loaded check valves when the effluent valve is opened. A typical design will require 3-4 feet of head differential between low water level in the decanted tank and high water elevation at the decanter discharge water elevation. Actual head requirements are reviewed and verified for each specific application. Utilizing this approach allows the Parkson design to eliminate motors, gears, drive units, and other electromechanical components from inside the basin. A simple open/close valve is used to control flow through the decanter. In-basin components are primarily stainless steel and fiberglass reinforced plastic (FRP). No in-basin components require routine maintenance or scheduled replacement.

For both DynaCanter decanter options, a cast in place wall spool (or supported spool for steel tanks or link seal designs) is located a few feet below minimum water level. The lower mitered elbow is bolted to the spool and is used to support the lower knee brace assembly. A wire reinforced flex hose is used to allow the decanter assembly to move up and down with changing water levels. An upper knee brace assembly is connected to the decanter drain tube and is pinned to the lower knee brace assembly to allow only vertical movement of the assembly. The drawtube (lower parallel pipe) houses the spring loaded check valves, or machined orifices, and is typically located 1-2 feet below the water surface to prevent vortexing and entrainment of floating materials. The upper parallel pipe is the foam filled float which provides buoyancy to the unit. The floating decanter rests are anchored to the tank floor and are designed to support the decanter when the tank is dewatered (and during initial installation). The supports also act as an emergency stop in the event that the effluent valve remains open after the decanter reaches bottom water level (this prevents the decanter from entering the sludge blanket).

The Parkson DynaCanter Design is Ideal for:

- Sequencing Batch Reactors

- Aerobic digester thickening

- Storm water retention tanks

- Equalization basins

- Water holding basins

- Basins requiring wide range of travel

- Cold weather installations

Looking for additional information? We're here to help.